Our Capabilities

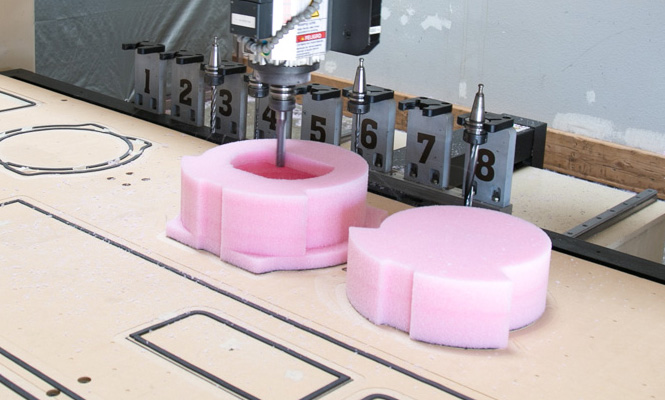

CNC Router

An automated process using end mill cutting. This process can be used to produce various depths and shapes in the material without the need for lamination or plugs. Specific sizes are created by using CAD programming.

Heat Laminator

An automated process of bonding material using heat and pressure through a roller system.

Contour Cutting

An automated process of using a thin blade in a horizontal or vertical position to contour cut or “Shape” material. This process can create various angles and dimensions. Specific shapes are created by using CAD programming.

Robotic Gluing

An automated process using a programmable robotic arm to dispense a hot melt adhesive to bond materials. This process is not only efficient and fast it provides location accuracy for the glue.

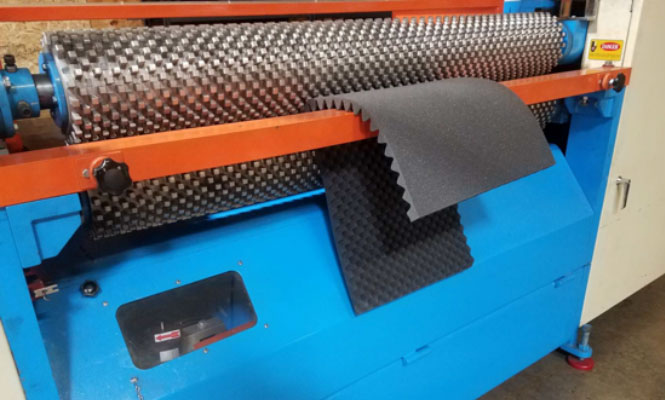

Convoluter

An automated process of cutting material to create peaks and valleys in foam commonly referred to as “Egg Crate”. This process uses a horizontal blade and textured rollers that can be adjusted in height to meet requirements.

Waterjet Cutting

An automated process of cutting material with a high pressure thin stream of water. This process provides accurate cutting, with ease of modifications without the need for tooling. CAD programming is utilized for design.

Steel Rule Die Cutting

An automated process of cutting material with a die using pressure. VFI utilizes multiple machines with various pressure tonnages from 45 to 250 tons. Specific shapes are created using CAD programming which is transferred to produce the cutting die shape.

Skiving

An automated process that utilizes a horizontal blade to sheet or “Skive” material to thickness. This process is generally used on closed cell materials.